Product Data Sheet |

|

TEFRO®floor PU COATINGSolvent free, flexible 2-component polyurethane resin for interior and exterior decks on ships. |

TEFRO®floor PU COATING meets the requirements of IMO FTP-Code 2010; it is a solvent-free, pigmented and flexible 2-component polyurethane resin, suitable for interior and exterior decks on ships. The PU coating can be used in various ways for example in areas with mechanical load or in areas where a high-end design finish is required. It meets the criteria of optical appearances of a design floor and can be sprinkled with colored flakes. An anti-slip effect is created, when fire-dried quartz-sand is sprinkled in the coating.

| • Solvent-free | • Anti-Slip possible | • Flexible |

| • Abrasion resistant | • Fillable with e.g. fire-dried quartz-sand | • Chemical resistant |

| • Water-impermeable | • Self-levelling | • Decorative design possible |

|

Mixing Ratio

|

|

100:20

|

|

|

|

VOC-Content

|

|

11,67

|

g/l

|

|

|

Density

|

DIN EN ISO 1183 -1

|

approx. 1,4

|

g/cm³

|

|

|

Mix Viscosity

|

|

2500 ± 300

|

mPa s

|

|

|

Solid Content

|

|

99,1

|

%

|

|

|

Shore - Hardness

|

DIN EN ISO 868

|

D 45

|

|

|

|

Fire rating

|

IMO FTP-Code 2010

|

Part 2 and Part 5

|

|

|

1 Unit = 12,0 kg (Comp. A + B = 10,0 kg + 2,0 kg)

Requirements

Substructures

a) Steel-decks

b) Aluminium decks and galvanized steel decks of interior and exterior areas

c) Cement-based substructures

d) EP-/PU-Surfaces

|

Temperature of Atmosphere

|

|

+10°C

|

+20°C

|

+30°C

|

|

Ready for foot traffic (h)

|

|

24

|

12

|

8

|

|

Ready to mechanical strain (d)

|

|

4

|

2

|

1

|

|

Ready to chemical strain (d)

|

|

7

|

4

|

3

|

|

Max. rel. humidity in (%)

|

|

80

|

80

|

80

|

|

Pot Life

|

approx. 60 minutes (+20°C)

|

|

Consumption

|

1,4 kg/m²/mm

|

|

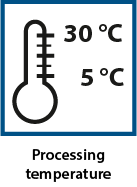

Temperature of Object

|

min. 5 °C and max. 30 °C

|

|

Product Temperature

|

min. 15 °C and max. 25 °C

|

Mixing

Application

Equipment and Cleaning

TEFRO®prime EP 30, TEFROKA®PU-1-L, TEFRO®floor EP, TEFROKA®KH - Filler, TEFROKA®EP-/PU Sealers, fire-dried quartz-sand

12 months, in a cool, dry, frost-free place in originally closed containers at 5 – 30 °C. In case of discrepancies please contact us!

• Grey, Beige, more color on request.

The color may vary between the batches, due to raw materials and the production process.

All mentioned figures and consumption values are results which were determined under laboratory conditions. When using the product on the job, deviating values may result. Lower temperatures delay; higher temperatures accelerate hardening and curing of the product. The specified minimum of the application temperatures have to be followed. No other materials may be added and the mixing ratios are not allowed to be changed.

The product meets the criteria of IMO FTP-Code 2010, attachment 1, Part 2 und 5. MED Certification and type approvals of other classification societies are available. The conformity is in accordance with the effective regulations 2014/90/EU of 23-July-2014. For the wheel symbol the general principles of article 30, paragraph 1, 3 and 6 of the regulation (EG) no. 765/2008 apply.

Read the hazard notes and safety advices as stated in the safety data sheets.

This product data sheet is based on the latest state of art and our experience and it is giving recommendations based on our best knowledge. However, it is without legal binding and establishes neither a contractual legal relationship, nor a secondary obligation on any sales contract. This product data sheet does not release the buyer or user of the obligation, to check the substructure and the material for the intended purpose. If the buyer or user is going to use the material differently than described above, it needs to be discussed with manufacturer before the application. Without approval of altered use of material, usage is at the buyers or users on risk. This refers especially to combinations with other products. Only product data sheets of latest date are valid.